Aircraft Consumables and Expendables

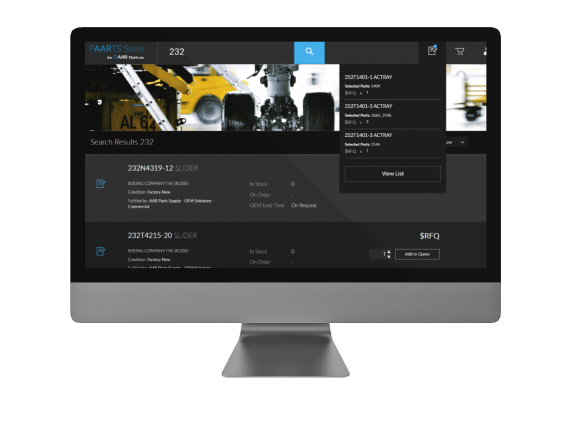

AAR offers customizable aircraft consumables and expendables programs supporting the entire supply chain. We act as your single point of contact, replacing hundreds of suppliers. Our experienced team focuses on your KPIs for aircraft parts, materials, warehouse operations, and quality control departments to deliver increased efficiency and performance at a lower total cost.

Support services for airline maintenance and operations centers

Our support services include planning, procurement, and supply management, ensuring a seamless flow of consumables and expendables. We incorporate advanced technologies, such as electronic data interchange (EDI) for transaction-level data exchange and complete emergency response plan (ERP) system integration for receiving and inspection, ensuring that every part meets stringent quality standards. We provide on-site program management support, offering expert oversight and coordination directly at your airline maintenance and operations centers to ensure correct implementation of aircraft consumables and expendables programs.

Customer results

Our focus on reducing customer-owned inventory and overhead associated with consumable and expendable management has led to significant cost savings and process efficiencies for our customers. This customer-centric approach has been instrumental in the continued growth and success of our programs.

Proven processes

Our material planning and sourcing processes are designed to meet the specific aviation demands of consumables and expendables. Our five-step material planning process includes:

- Understanding demand drivers

- Building routine forecast

- Building non-routine forecast

- Integrating routine and non-routine forecasts for given site

- Refining forecasts

Our sourcing process includes:

- Profiling sourcing group

- Selecting sourcing strategy

- Generating supplier portfolio

- Negotiating and selecting suppliers

- Integrating suppliers

- Benchmarking supply market

Our consumables and expendables stats

- 98% average fill rate

- 200+ supplier resources

- 40,000+ consumable and expendable parts managed